Resumo

Foram realizados dois experimentos com o objetivo de avaliar a composição nutricional e a utilização de diferentes níveis de inclusão de resíduo de biscoito tipo wafer (RB), na alimentação de codornas europeias, sobre o desempenho produtivo, rendimento de carcaça e viabilidade econômica. No ensaio de metabolizabilidade, o RB apresentou 87,45% de MS, EB de 4.128,53 kcal/kg, EMA de 3.833,14 kcal/kg, EMAn de 3.818,92 kcal/kg, com 9,37% de PB e 17% de EE. Os valores do coeficiente de metabolizabilidade (CM) para MS, EB, EE e PB foram: 93,20; 92,85; 93,01 e 47,16%, respectivamente. No ensaio de desempenho, houve redução linear (P<0,05) do consumo de ração das aves nos períodos de 22 a 42 dias e de um a 42 dias de idade. O ganho de peso e a conversão alimentar das aves não foram influenciados (P>0,05) pela inclusão do RB. Não houve efeito (P>0,05) dos níveis de inclusão do RB sobre o rendimento de carcaça. A ração com 20% demonstra ser mais rentável. Recomenda-se a inclusão do RB até o nível de 20% nas dietas para codornas, sem comprometer o desempenho produtivo, o rendimento de carcaça e a viabilidade econômica.

Palavras-chave: coturnicultura; metabolismo; nutrição; subproduto da agroindústria.

Section: Zootecnia

Received

November 20, 2018.

Accepted

November 25, 2019.

Published

June 16, 2020.

www.revistas.ufg.br/vet

visit the website to get the how to cite in the article page.

Introduction

Poultry farming is considered a segment of great importance in the production of high-protein foods, where producers are always seeking to adapt to the new techniques to improve animal production efficiency(1,2). In this scenario, quail production has stood out in the Brazilian poultry sector due to the low investment required for the activity and the rapid growth, early development, high productivity and sexual maturity of the species. However, feeding is highlighted as one of the factors of greatest relevance, as it accounts for around 70% of total quail production costs(3,4). Therefore, new feedstuffs should be sought to replace those traditionally used such as maize and soybean meal, which are the main responsible for the high costs of poultry production systems. Cost reduction should thus be prioritized considering the regional availability and quality of the product as well as its environmental pollution potential(1,5).

Some of the alternative feedstuffs are those derived from the food industry. This industry has generated a considerable amount of waste, raising great concern for regulatory agencies in terms of the final destination of this waste, which is commonly discarded in the environment, causing the most diverse environmental problems(6,7). The biscuit industry is no different, generating large amounts of waste due to inadequacy in the processes of production and distribution to the final consumer that usually stems from losses due to breaking or excess or insufficient cooking during processing. This waste can, however, be considered a sustainable alternative when used in animal feeding. It may also include unmarketed products or products past the expiration date, characterized as not approved by the quality control sector of factories(8-12).

Waste from the biscuit industry can have variable compositions, which depend on the formula and ingredients used. Biscuit waste is considered a high-energy source, given its starch, sugar, fat, protein and lysine contents that are similar to those of maize, but higher sodium levels(11). A study led by Nunes et al.(13) revealed metabolizable energy values of 4,480 and 4,105 kcal/kg in biscuit and pasta wastes, respectively, when fed to broiler chicks. According to Rostagno et al.(14), the protein and energy contents of biscuit waste are 8.69% and 4,010 kcal/kg, respectively, with metabolizable energy values higher than those found in maize. The nutritional value of biscuit waste described in the literature is thus inferred to provide a great energy uptake, similarly to high-energy grains, which has aroused interest in this ingredient as a partial substitute for maize in the diet of non-ruminants(11,15).

Shittu et al.(16) tested different levels of biscuit waste inclusion in the diet of broiler chickens and found that it can replace up to 15% of maize during the starter and finisher phases of rearing without compromising performance, nutrient digestibility or carcass characteristics.

On the basis of the foregoing, the present study proposes to determine the chemical and energy composition and the metabolizability of wafer-type biscuit waste as well as examine the effect of its inclusion in meat-quail diets on production performance, carcass characteristics and economic viability in the period of one to 42 days of age.

Materials and methods

The experiment was carried out in the Quail Farming unit of CECA/UFAL, located in Rio Largo - AL, Brazil. All procedures were approved by the Ethics Committee on Animal Use of the Federal University of Alagoas (approval nº. 27/2017).

Experiment I – Metabolizability trial

The wafer-type biscuit waste (WW) was acquired from the Pandurata Alimentos company, located in the municipality of Rio Largo - AL, Brazil. The waste originated from discard at the production line of the company, in the form of pressed sheets without filling, which were ground through 6-mm sieves to obtain the biscuit waste meal that was used to compose the diets. The chemical composition of WW was determined by analyzing the dry matter (DM), crude protein (CP), ether extract (EE), mineral matter (MM) and gross energy contents (GE), following the methodology proposed by Silva & Queiroz(17).

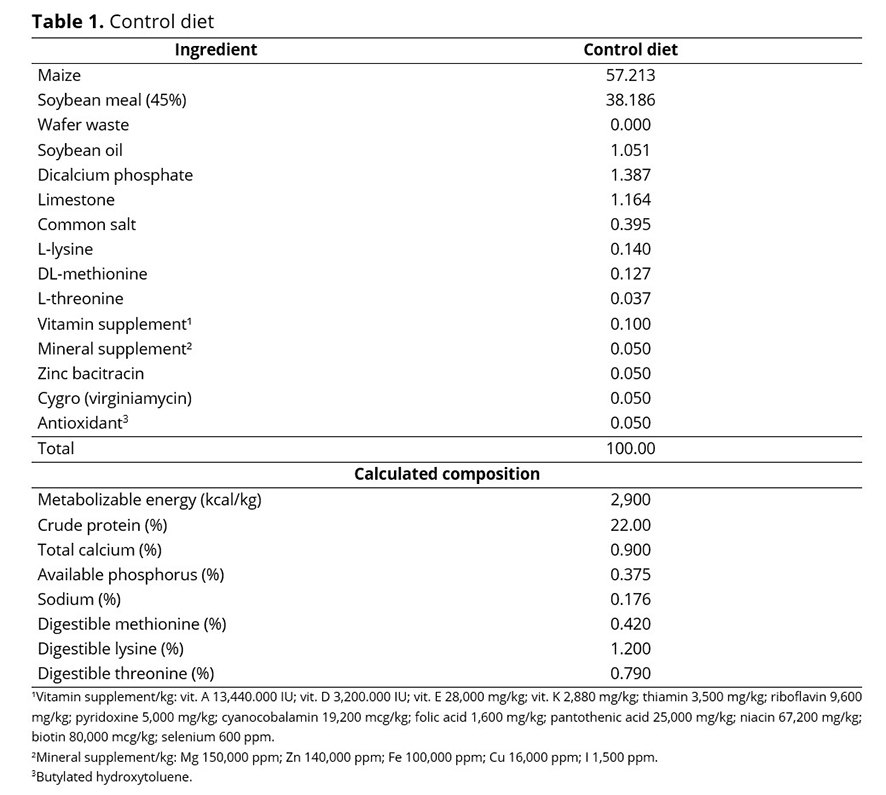

One hundred 21-day-old European quail were used for the WW metabolizability trial. The birds were allocated to two treatments (control diet - 0% biscuit waste; and test diet - 20% biscuit waste) in a completely randomized design with five replicates and 10 birds per experimental unit. The experimental diets (Table 1) were formulated following the nutritional recommendations of Rostagno et al.(18).

The experimental period was 10 days, consisting of five days of adaptation to the diet and management and five days of excreta collection. The total excreta collection method was adopted, with start and end determined based on the appearance of marked excreta (1.0% Fe2O3 added to the diets), as described by Sibbald & Slinger(19). The apparent metabolizability coefficients of DM and GE and the apparent metabolizable energy (AME) and nitrogen-corrected AME (AMEn) values of the diets were calculated using formulae proposed by Matterson et al.(20).

For the excreta collection, trays lined with plastic, from the very cage, were placed under each compartment so as to individualize the material and prevent contaminations and losses. The collected excreta were weighed, packed in labeled plastic bags and frozen at -18 ºC. At the end of the experimental period, they were homogenized and dried in a forced-air oven (55 ºC for 72 h) and ground for later analyses. The amounts of feed consumed and the total excreta produced per experimental unit were determined. Chemical analyses of diets and excreta were performed at the Laboratory of Animal Nutrition of UFPB according to methodologies described by Silva & Queiroz(17).

The metabolizability coefficients of DM, GE, CP and EE were calculated using formulae proposed by Matterson et al.(11). The AME and AMEn values of the diets and waste were calculated using the results of the laboratory analysis of feed and excreta. Data were subjected to analysis of variance (P<0.05) using R Core Team software(21).

Experiment II - Performance, carcass yield and economic viability

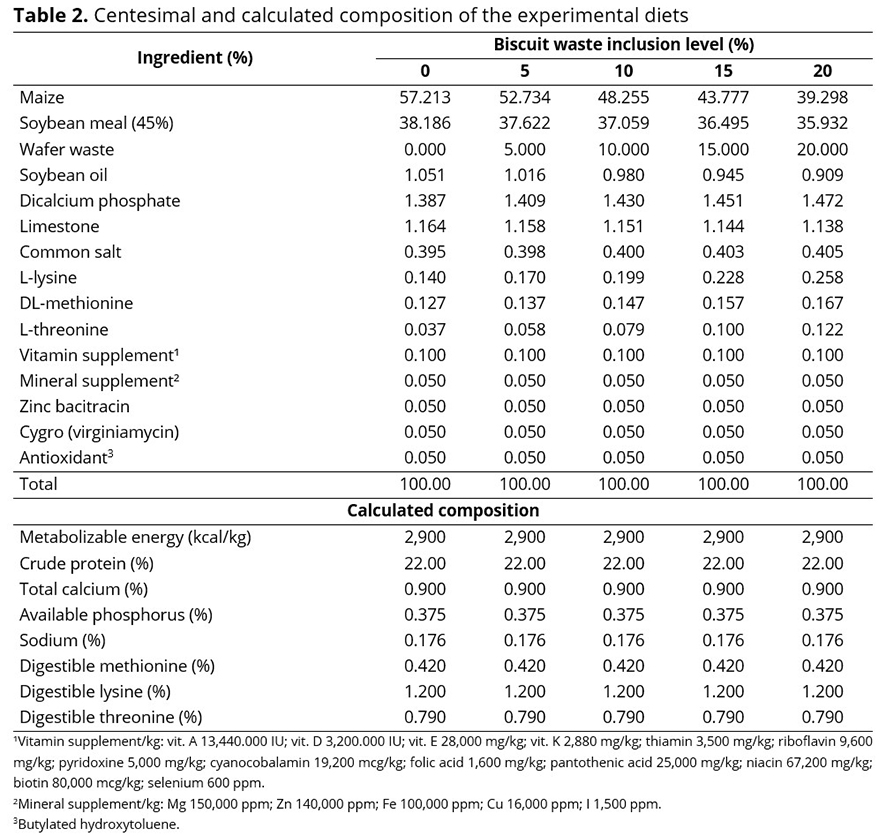

A total of 250 one-day-old mixed European quail with an average initial weight of 9.14 ± 0.27 g were allocated to five treatments (control diet and diets with 0, 5, 10, 15 and 20% inclusion of biscuit waste) in a completely randomized design with five replicates and 10 birds per plot, totaling 25 experimental units. The birds were housed in galvanized-wire battery cages (50 × 60 × 30 cm) in an air-conditioned room. The cages were equipped with trough feeders, syphon drinkers and an excreta-collection tray.

The climatic conditions in the room were measured daily, at 08h00 and 16h00, using a maximum-minimum thermometer, a black-globe thermometer and a thermohygrometer. The black-globe humidity index (BGHI) was calculated by the formula proposed by Buffington et al.(22). The following mean maximum and minimum temperatures, air relative humidity and BGHI values were recorded during the experimental period: 26.94 ± 2.63 ºC, 25.65 ± 2.50 ºC, 88.51 ± 3.91% and 76.92%, respectively.

Water and feed were available ad libitum from one to 42 days of age. The diets (Table 2) were maize- and soybean meal-based and formulated according to the nutritional requirements recommended by Rostagno et al.(18), containing equal levels of protein, energy and amino acids. The chemical composition values of the biscuit waste obtained in the metabolizability trial were used for its inclusion in the formulated diets.

Birds, supplied feed and orts were weighed weekly for the calculation of the following performance indices: feed intake, weight gain and feed conversion. At 42 days of age, two birds (one male and one female) representing the average weight of the experimental plot were selected per unit. After a six-hour feed-deprivation period, the birds were slaughtered, plucked and subsequently eviscerated for the cuts to be removed and carcass yield determined.

The following parameters were evaluated: absolute (grams) and relative (%) weights of carcass, prime cuts (breast and legs) and edible offal (heart, liver and gizzard). After the carcasses were weighed, the relative weight (%) was calculated in relation to the post-fasting live weight, using the following formula: Carcass yield (%) = (carcass weight/live weight × 100). The percentage yield of cuts and edible offal was determined as a function of the eviscerated carcass with feet, by the following formula:

Cut or offal yield (%) = (cut or offal weight/carcass weight × 100).

Economic viability was determined as a function of changes in live weight, feed intake and diet costs, which depended on the waste inclusion levels, in accordance with the methodology described by Lana(4). The sale price of the live quail and the prices of the raw materials used in the calculation of diet costs corresponded to those charged during the development of the experiment. Each one-day-old quail was purchased at BRL 1.40, and its sale (kilogram of slaughtered quail) was estimated at BRL 16.00. The ingredients used in the diet formulation were purchased at the following prices (per kg): maize - BRL 1.25; soybean meal - BRL 1.45; wafer waste - BRL 0.30; soybean oil - BRL 3.95; dicalcium phosphate - BRL 6.00; limestone - BRL 0.27; common salt - BRL 0.85; lysine - BRL 9.00; methionine - BRL 25.00; threonine - BRL 11.00; vitamin supplement - BRL 20.00; mineral supplement - BRL 10.00; zinc bacitracin - BRL 15.00; Cygro - BRL 46.00; BHT - BRL 37.00.

Statistical analyses of the variables were performed using R Core Team software(21). Results were subjected to analysis of variance at the 5% probability levels and means showing significant differences (P<0.05) were subjected to regression analysis.

Results and discussion

Experiment I

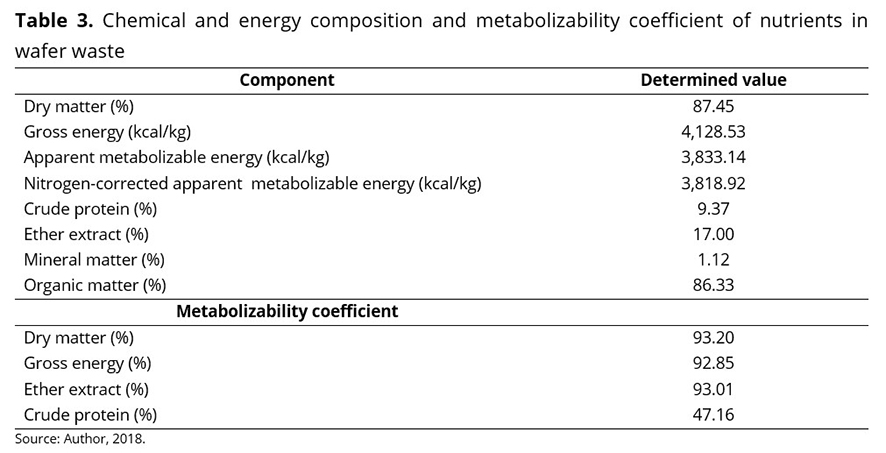

Table 3 shows the chemical and energy composition values and the metabolizability coefficients of WW.

The DM content of the waste was 87.45%, which is close to the 92.24% found by Volpato et al.(7), who evaluated sweet-biscuit waste; the 92.40% determined in biscuit waste by Tardocchi et al.(23); and the 91.07% found in biscuit waste meal by Corassa et al.(11).

The WW had a gross energy content of 4,128.53 kcal/kg. This value is higher than the minimum and maximum GE contents of 3,200 and 4,485 kcal/kg reported by Corassa et al.(11), respectively. By contrast, Volpato et al.(7) described a GE content of 4,494 kcal/kg in sweet-biscuit waste.

The AME and AMEn values found in the current study were similar to the 3,959 and 3,480 kcal/kg, respectively, found by Oliveira et al.(24), in cracker and biscuit waste in a metabolism trial with 16-day-old broiler chickens, using the waste at a replacement level of 30% in control diet.

Rostagno et al.(14) reported similar AME values (4,010 kcal/kg) for cracker and biscuit waste in a metabolism trial with broiler chickens from 16 to 24 days of age. However, an experiment led by Nunes et al.(13) involving 40% biscuit waste replacing control diet for broiler chickens revealed higher AME and AMEn values: 4,480 and 4,339 kcal/kg, respectively.

The CP contents found in WW was 9.37%, which is considerably lower than the 19.25% found by Shittu et al.(16) in biscuit waste. However, the current result is close to the 9.07 and 8.38% CP obtained by Corassa et al.(11) and Nunes et al.(13), respectively, in biscuit waste.

The EE content of 17% found in the waste is higher than the values around 12% described by Tardocchi et al.(23) in biscuit waste and by Volpato et al.(7) in sweet biscuit.

There is a great variability in the chemical composition of biscuit meal in the literature, which is due to the fact that the product is formed by waste that is often inconstant, thus altering the material composition. Additionally, few studies describe the type of biscuit used.

The organic and mineral matter contents of WW were 86.33 and 1.12%, respectively, which are similar values to those found by Corassa et al.(11) in biscuit waste.

The metabolizability coefficients of DM, GE, CP and EE found in the waste were 93.20, 92.85, 47.16 and 93.01%, respectively.

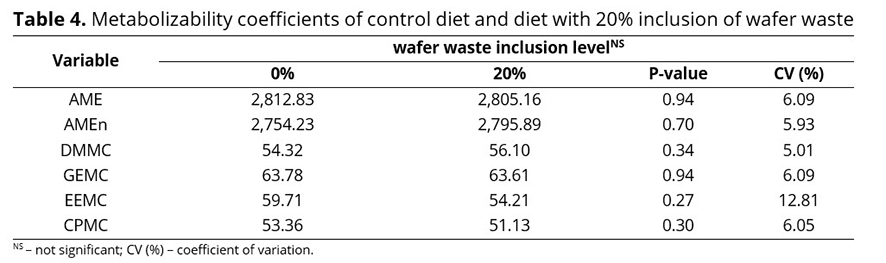

Table 4 shows the AME and AMEn values and the metabolizability coefficients of control diet and the test diet containing 20% WW.

There was no significant effect (P>0.05) for AME, AMEn or the metabolizability coefficients of DM, GE, EE and CP. These results demonstrate the similarity between the treatments with 0% and 20% inclusion of the waste.

The mean AME values were 2,812.83 and 2,805.16 kcal/kg and the mean AMEn values were 2,754.23 and 2,795.89 kcal/kg for the WW inclusion levels of 0% and 20%, respectively. According to Nunes et al.(13), differences in metabolizable energy values can be used to evaluate feedstuffs with high energy contents when the AME value is above 2,500 kcal/kg, which was found in the present experiment.

The DM metabolizability coefficients found in the biscuit waste were 54.32 and 56.10% for the respective dietary inclusion levels of 0 and 20%.

High GE metabolizability coefficients were found in the waste: 63.78 and 63.61% for the inclusion levels of 0 and 20%, respectively. The mean EE metabolizability coefficients were 59.71 and 54.21% for the same inclusion levels. Considering the obtained results for the metabolizability coefficients of these two components, it can be stated that the meat quail efficiently utilized the energy present in this waste. Wafer waste can thus be considered a high-energy feedstuff, given the EE contents present in the ingredients used in its manufacture besides the high metabolizability values found.

Experiment II

Crude protein metabolizability coefficients of 53.36 and 51.13% were detected in the biscuit waste at the dietary inclusion levels of 0 and 20%, respectively.

It is important to consider that there is a great divergence in the literature regarding the nutritional value of this feedstuff, which may change depending on the technological process to which it was subjected(25,26); the existing variations between the soils and climates where the wheat grain was cultivated; the species that will utilize it; environmental conditions; nutrient quantity and quality; and proportion relative to other nutrients, which may lead to alterations in its composition and digestibility, as well as other factors(27-29).

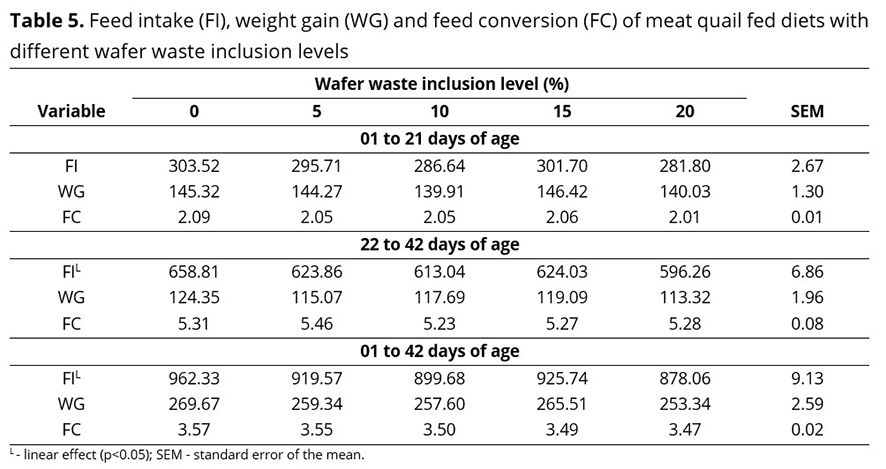

Results pertaining to the performance of meat quail fed diets with different WW inclusion levels are given in Table 5. From one to 2 days of age, the WW inclusion levels had no effect (P>0.05) on feed intake, weight gain or feed conversion.

However, in the periods of 22 to 42 and one to 42 days of age, feed intake decreased linearly (P<0.05) by 0.8324 and 0.5414 g, respectively, with every percentage unit of the waste added to the diet, as shown by the following equations:

Ŷ = 216.06 - 0.8324x (R²=0.74) and Ŷ = 158.26 - 0.5414x (R²=0.67). This decrease in feed intake may be related to a possible behavioral response, as the birds selected the larger particles. These findings corroborate those described by Adeyemo et al.(30), who worked with biscuit waste in the feeding of chickens and noted that feed intake decreased as the inclusion levels were increased, although feed conversion was not compromised. It should be stressed, however, that despite the drop in feed intake, weight gain and feed conversion were not influenced by the waste inclusion levels.

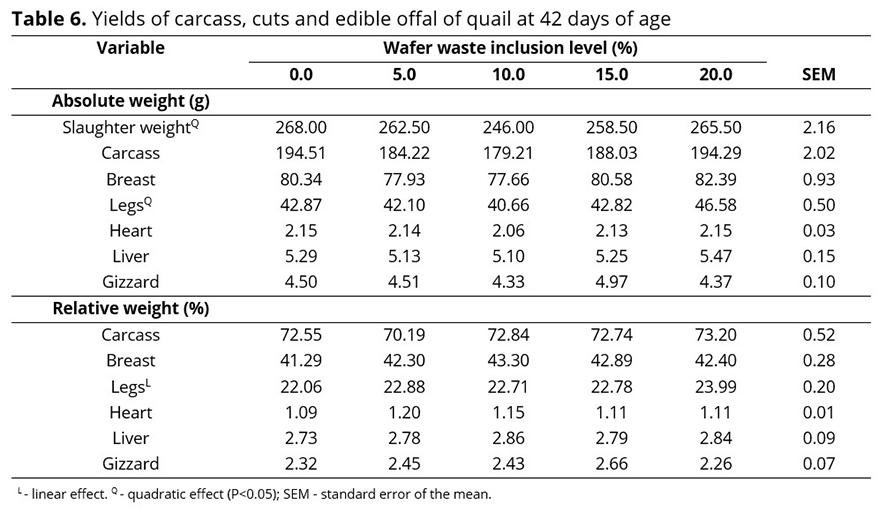

Results for the yields of carcass, cuts and edible offal of quail at 42 days of age are described in Table 6.

The absolute and relative weights of carcass, breast, heart, liver and gizzard were not influenced (P>0.05) by the WW inclusion levels. The different WW inclusion levels did not compromise the yields of carcass or edible offal from the quail. Similarly, Shahryar et al.(31) observed an increase in the blood glucose levels of broiler chickens fed diets with 24% WW but no negative impacts on carcass yield, which was attributed to the fact that the wafer biscuit efficiently contributed to the gluconeogenesis process. On the other hand, studies conducted by Ayanrinde et al.(32) described a reduction in gizzard size in broiler chickens fed increasing levels of bakery waste due to the reduced mechanical work of that organ.

Slaughter weight and the absolute weight of legs responded quadratically (P<0.05) to the WW inclusion levels, as can be seen by the following equations:

Ŷ = 269.61 - 3.2657x + 0.1543x2 (R²=0.72) and Ŷ = 43.187 - 0.5606x + 0.0362x2 (R²= 0.94), respectively. The relative weight of the birds at 42 days of age rose linearly, by 0.0752%, at every 1% inclusion of the waste in the diet, according to the following equation:

Ŷ = 22.132+0.0752x (R²=0.73).

This effect on slaughter weight may be related to the choice of the birds to be used in the experiment, which was based on the average weight of the plot.

Results for economic viability are presented in Table 7. Economic viability was inherent to the production and feeding components, considering that variations in production costs were dependent on differences in feed intake between the different levels to which the birds were subjected.

The treatment with 20% inclusion of WW resulted in lower average live weight and feed intake values than those obtained without waste inclusion, demonstrating the existence of some proportionality between the acquired weight and the consumed feed. The lowest feed cost was obtained with the diet with the WW inclusion level of 20%, with a BRL 0.04 reduction per kilogram of diet expected at each of the tested levels. Consequently, the lowest average feeding cost was also obtained with the diet with 20% inclusion of WW.

Average gross revenue was highest for the treatment with 0% inclusion of the waste. However, considering the average gross margin, it is clear that the lowest feed cost obtained using the treatment with the 20% inclusion level would provide the highest financial return after the initial costs are discounted, representing a relative gross margin of 16.56%.

The diet with 20% inclusion of WW showed to be the most profitable, providing a 42.74% higher financial return than control diet. Biscuit waste is characterized as a low-cost ingredient that allows a reduction in the use of corn and soybean oil, which are commonly included in poultry diets. Our findings corroborate the results published by Omoikhoje et al.(10), who concluded that greater economic return in chicken farming is achieved when using diets containing 50% biscuit waste, as compared with lower inclusion levels.

Conclusions

Wafer-type biscuit waste can be included up to the level of 20% in diets for meat quail without compromising production performance, carcass yield or the economic viability of the system.

Acknowledgments

The present study was supported by the Coordination for the Improvement of Higher Education Personnel - Brazil (CAPES), Finance Code 001; and the Alagoas State Research Support Foundation (FAPEAL).

References

1. Ashour EA, Reda FM, Alagawany M. Effect of graded replacement of corn by broken Rice in growing japanese quail diets on growth performance, carcass traits and economics. Asian Journal of Animal Science. 2015; 9(6): 404-411.

2. Cullere M, Tasoniero G, Giaccone V, Miotti-Scapin R, Claeys E, Smet S. Black soldier fly as dietary protein source for broiler quails: apparent digestibility, excreta microbial load, feed choice, performance, carcass and meat traits. Animal Journal. 2016; 10(12): 1923-1930.

3. Rufino JPF, Cruz FGG, Miller WPM, Melo RD, Feijó JC, Chagas EO. Análise econômica da inclusão de farinha do resíduo de tucumã (Astrocaryum vulgare, Mart) na alimentação de poedeiras comerciais. Revista Brasileira de Saúde e Produção Animal. 2015; 16(1):1-9.

4. Lana GRQ. Avicultura. Rural. 2000; 268 p. Portuguese.

5. Silva EA, Albino LFT, Rostagno HS, Ribeiro Junior V, Vieira RA, Campos AMA. et al. Chemical composition and metabolizable energy values of feedstuffs for broiler chickens. Revista Brasileira de Zootecnia. 2012; 41(3): 648-654.

6. Barros Júnior RF, Lana GRQ, Lana SRV, Leão APA, Ayres IC, Santos DS, Lima LAA, Silva WA. Resíduo da polpa do maracujá como alimento alternativo para codornas europeias fêmeas. 2018; 16: 9-12. Portuguese.

7. Volpato RM, Oliveira V, Gewehr CE, Neto DP. Coprodutos da agroindústria na alimentação de leitões. Ciência Rural. 2015; 45(1): 86-91. Portuguese.

8. Moretto E, Fett R. Processamento e análise de biscoito. São Paulo: Varela. 1999. 98p. Portuguese.

9. Lima MR, Ludke M.M. Utilização de ingredientes energéticos pela tilápia do Nilo. Revista Eletrônica Nutritime. 2011; 8(2): 1418-1430. Portuguese.

10. Omoikhoje SO, Oduduru O, Eguaoje SA. Effect of substituting maize with biscuit waste meal on the growth performance, carcass traits, relative organ weight and cost benefit of broiler chickens. Animal Research International. 2017; 14(2): 2751-2758.

11. Corassa A, Prezotto RT, Komiyama CM, Moreira PSA, Araújo CV. Farelo de biscoito na alimentação de porcas em lactação. Pesquisa Agropecuária Tropical. 2014; 44(1): 42-49. Portuguese.

12. Santos GRA, Queiroz LO, Silva MA, Andrade ACS, Souza EJO. Substituição do milho por resíduo de panificação na dieta de ovinos: consumo e digestibilidade aparente. B. Indústr. Anim. 2014; 71(2): 154-159. Portuguese.

13. Nunes RV, Rostagno HS, Albino LFT, Gomes PC, Toledo RS. Composição bromatológica, energia metabolizável e equações de predição da energia do grão e de subprodutos do trigo para pintos de corte. Rev. Bras. Zootec. 2001; 30(3): 785-793. Portuguese.

14. Rostagno HS, Albino LFT, Hannas MI, Donzele JL, Sakomura NK, Perazzo FG. et al. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 4. ed. Viçosa (MG): Universidade Federal de Viçosa; 2017. 488p. Portuguese.

15.Paes JPS, Freitas HJ, Cordeiro MB. Utilização de farelo de macarrão na alimentação de frangos de corte de linhagem caipira. Enciclopédia Biosfera. 2015; 11(21): 1897-1902.

16. Shittu MD, Ojebiyi OO, Ademola SG, Ojediran TK. Replacement value of biscuit dough for maize on performance and nutrient utilization of broiler chickens. International Journal of Science, Environment and Technology. 2016; 5(3): 1057–1065.

17. Silva DJ, Queiroz AC. Análise de alimentos: métodos químicos e biológicos. 3. ed. Viçosa (MG): Universidade Federal de Viçosa; 2002. Portuguese.

18. Rostagno HS, Albino LFT, Donzele JL, Gomes PC, Oliveira RF, Lopes DC. et al. Tabelas brasileiras para aves e suínos: composição de alimentos e exigências nutricionais. 3. ed. Viçosa (MG): Universidade Federal de Viçosa; 2011. Portuguese.

19. Sibbald JR, Slinger SJ. A biological assay for metabolizable energy in poultry feed ingredientes together with findings which demonstrate some of the problems associated with the evaliation of fats. Poultry Science, Champaign. 1963; 42(2): 313-325.

20. Matterson LD, Potter LM, Stutz MW, Singsen EP. The metabolizable of feeds ingredient for chickens. Storrs: University of Connecticut – Agricultural Experiment Station. 1965; 11(7).

21. R Development Core Team: 'A language and environment for statistical computing'. Vienna: R Foundation for Statistical Computing, 2016.

22. Buffington DE, Collazo-Arocho A, Canton GH, Pitt D, Thatcher W, Collier R. Black globe-humidity índex (BGHI) as comfort equation for dairy cows. American Society of Agricultural Engineers. 1981; 24(3): 711-714.

23. Tardocchi CFT, Soares RTRN, Bonaparte TP, Cabral NO. Digestibilidade de resíduos agroindustriais para suínos na fase inicial. Revista Eletrônica Nutritime. 2014; 11(6): 3770-3780. Portuguese.

24. Oliveira HF, Santos JS, Cunha FSA. Utilização de alimentos alternativos na alimentação de codornas. Revista Eletrônica Nutritime. 2014; 11(5): 3683-3690. Portuguese.

25. Troni AR, Gomes PC, Mello HHC, Albino LFT, Rocha, TC. Composição química e energética de alimentos para frangos de corte. Rev. Ciên. Agron. 2016; 47(4): 755-760. Portuguese.

26. Parpinelli, W, Cella PS, Savaris VDL, Broch J, Nunes RV. Dry brewery residue in broiler chickens feed. Semina: Ciências Agrárias. 2018; 39(4): 1707-1716.

27. Santos FR, Stringhini JH, Minafra CS, Almeida CS, Oliveira PR, Duarte EF, Silva RB, Café MB. Formulação de ração para frangos de corte de crescimento lento utilizando valores de energia metabolizável dos ingredientes determinada com linhagens de crescimento lento e rápido. Arq. Bras. Med. Vet. Zootec. 2014; 66(6): 1839-1846. Portuguese.

28. Bergamin GT, Veiverberg CA, Siqueira LV, Eggers DP, Neto JR. Digestibilidade aparente de farelos vegetais tratados para remoção de antinutrientes em dietas para jundiá. Pesq. Agropec. Bras. 2013; 48(8): 928-934. Portuguese.

29. Cornélio FHG, Cargnin-Ferreira E, Boraba MR, Mouriño JLP, Fernandes VAG, Fracalossi DM. Crescimento, digestibilidade e resistência à infecção por patógeno em tilápia-do-nilo alimentada com probióticos. Pesquisa Agropecuária Brasileira. 2013; 48(8): 863-870. Portuguese.

30. Adeyemo GO, Oni OR, Longe OG. Effect of dietary biscuit waste on performance and carcass characteristics of broilers. Food Science and Quality Management. 2013; 12: 1-9.

31. Shahryar HA, Nobakht A, Ahmadzadeh A, Lofti A. Possibilities of using biscuit or wafer waste in broiler chicken diets. Kafkas Univ Vet Fak Derg. 2012; 18(5): 759-762.

32. Ayanrinde OJ, Owosibo OJ, Adeyemo AA. Performance characteristics of broilers fed Bread waste based diets. International Journal of Modern Plant & Animal Science. 2014; 2(1): 1-11.